FIBRE TO FABRIC CROWD FUNDING CAMPAIGN

Mourne Textiles need your support for their project aimed at not only preserving but bringing to life the exceptional heritage of the Northern Ireland textile industry. With a belief in a green and sustainable future, where innovation meets tradition and tradition informs innovation, they are on a mission to restore vintage flax processing and spinning equipment and to revive the full natural fibre manufacturing process. They are inviting you to celebrate and learn from their shared history while creating a new industry that is sustainable, non-polluting, and fit for the 21st century.

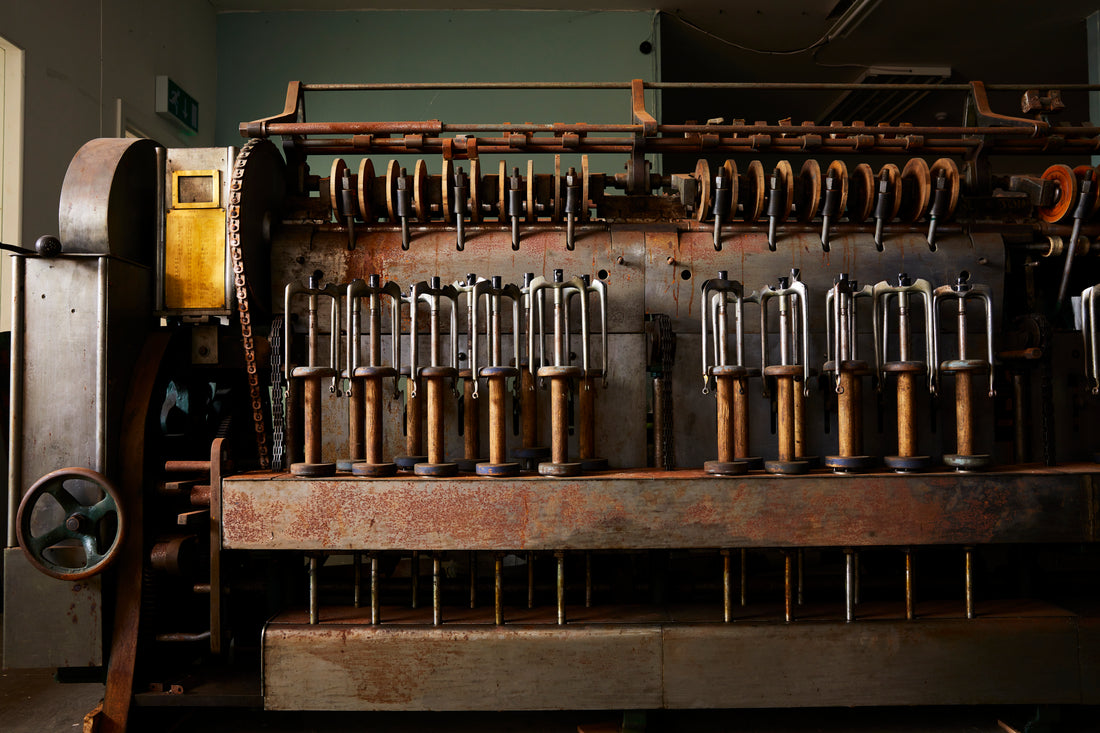

Image and image above courtesy of Mourne Textiles

Their mission is to develop a new net-zero raw material supply chain for high value manufacturing industries, rejuvenating equipment, and technology to deliver that based on a shared history. Mourne Textiles plan to locate and learn from those who worked in the industry, celebrating and recording these skills. By logging and learning from our shared history, we can create new wealth and valuable skills for generations to come. The project has tremendous historical value to Northern Ireland and the weaving industry, and we need your support to make it a reality. They invite you to celebrate our heritage and shaping a brighter future through the power of textiles, “Fibre to Fabric”.

Image: brining in the flax harvest. Image courtesy of Mallon Linen

Mourne Textiles discovered a complete set of industrial flax spinning machines while searching for vintage power looms in old derelict linen mills. Although old, these machines are still very relevant today for processing flax, hemp, and possibly nettle fibres once they have been harvested, scutched, and heckled. In collaboration with local farmers at Mallon Linen, they aim to promote sustainable fabric production here on the Island of Ireland, by creating a field-to-fabric circular supply chain. With a focus on producing environmentally friendly fabrics grown and processed locally, they plan to restore the flax processing and spinning equipment, which is the missing link required to process flax fibres into yarn. Bringing these renowned textile brands, Mackies and Combe Barbour, which are synonymous with Northern Ireland Linen industry, back into production.

Image courtesy of Mourne Textiles

They have also obtained an industrial power loom to produce narrow-width linen and selvedge denim. This Atherton loom is a recognised textile brand that we are excited to restore to create sustainable Irish Selvedge denim - truly promoting our heritage and craftsmanship.

The second phase of the project is to create a unique ‘Micro Spinning Mill’ using these vintage machines, training a new generation of skilled craftsmen and opening the doors to visitors as a living, working museum. Recording and securing our textile heritage for future generations while learning from our shared history. This will enable visitors to learn about the production techniques used in the past and see the production process first hand.

Find out more and support Mourne Textiles:

www.mournetextiles.com

@mournetextiles

Image and image above courtesy of Mourne Textiles

Their mission is to develop a new net-zero raw material supply chain for high value manufacturing industries, rejuvenating equipment, and technology to deliver that based on a shared history. Mourne Textiles plan to locate and learn from those who worked in the industry, celebrating and recording these skills. By logging and learning from our shared history, we can create new wealth and valuable skills for generations to come. The project has tremendous historical value to Northern Ireland and the weaving industry, and we need your support to make it a reality. They invite you to celebrate our heritage and shaping a brighter future through the power of textiles, “Fibre to Fabric”.

Image: brining in the flax harvest. Image courtesy of Mallon Linen

Mourne Textiles discovered a complete set of industrial flax spinning machines while searching for vintage power looms in old derelict linen mills. Although old, these machines are still very relevant today for processing flax, hemp, and possibly nettle fibres once they have been harvested, scutched, and heckled. In collaboration with local farmers at Mallon Linen, they aim to promote sustainable fabric production here on the Island of Ireland, by creating a field-to-fabric circular supply chain. With a focus on producing environmentally friendly fabrics grown and processed locally, they plan to restore the flax processing and spinning equipment, which is the missing link required to process flax fibres into yarn. Bringing these renowned textile brands, Mackies and Combe Barbour, which are synonymous with Northern Ireland Linen industry, back into production.

Image courtesy of Mourne Textiles

They have also obtained an industrial power loom to produce narrow-width linen and selvedge denim. This Atherton loom is a recognised textile brand that we are excited to restore to create sustainable Irish Selvedge denim - truly promoting our heritage and craftsmanship.

The second phase of the project is to create a unique ‘Micro Spinning Mill’ using these vintage machines, training a new generation of skilled craftsmen and opening the doors to visitors as a living, working museum. Recording and securing our textile heritage for future generations while learning from our shared history. This will enable visitors to learn about the production techniques used in the past and see the production process first hand.

Find out more and support Mourne Textiles:

www.mournetextiles.com

@mournetextiles